Acrylic Sheet

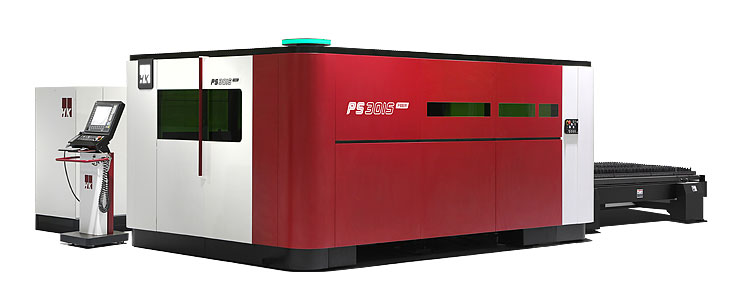

Fiber laser cutting machines can be used to cut many metal materials (sheet, tube, metal profile and 3D curved and irregular metals), such as carbon steel.

Laser cutting systems can be used for industrial manufacturing, commercial usage, school education, school education, small business and home business, small shop, shop, hobbyist, craftsman, and small business.